Vegetable Drying Machine (Heat Pump Dehydrator)

For large-scale commercial vegetable processors, food factories, or suppliers providing dried vegetables to food manufacturers, ready-meal producers, or the export market, our vegetable drying machine is the optimal solution for integration with your existing drying rooms.

It features a unique multi-loop system for high efficiency, uniform temperature control, and a 20-30% increase in dehumidification.

This dryer also offers multiple operating modes, including open-loop and closed-loop drying, making it perfectly suited for large drying chambers that balance high output with low energy consumption.

- Power: 18.5 kW, 37 kW

- Voltage: 380V/3Ph/50Hz

- Dehydration Amount: 20 kg/h, 38 kg/h

- Max Air Outlet Temperature: 75°C (167°F )

How ZN Heat Pump Dehydrator Works?

ZN Vegetable Drying Machine Working Process

A heat pump dehydrator acts as an efficient “heat mover” moving heat from the outside air into the drying chamber to dry vegetables in an energy-saving way. The entire process is electric-driven, yet it saves 50-70% more electricity than traditional electric heating and offers automatic temperature and humidity control for simple operation.

Heat Absorption (Evaporation): The evaporator acts like a “heat sponge,” pulling warmth from the air, which makes the refrigerant evaporate into a low-temperature, low-pressure gas.

Compression & Heating: The compressor then “squeezes” this gas, making it high-temperature and high-pressure.

Heat Release (Condensation): The condenser releases this heat, warming the drying chamber’s air. This hot air then circulates over your vegetables, efficiently removing moisture.

Expansion & Cooling: The refrigerant goes through an expansion valve, dropping in pressure and cooling back into a liquid, ready to start the cycle again.

Humidity Control: A specialized dehumidification system removes moisture, keeping the drying chamber perfectly dry.

Key Points for Perfect Vegetable Drying

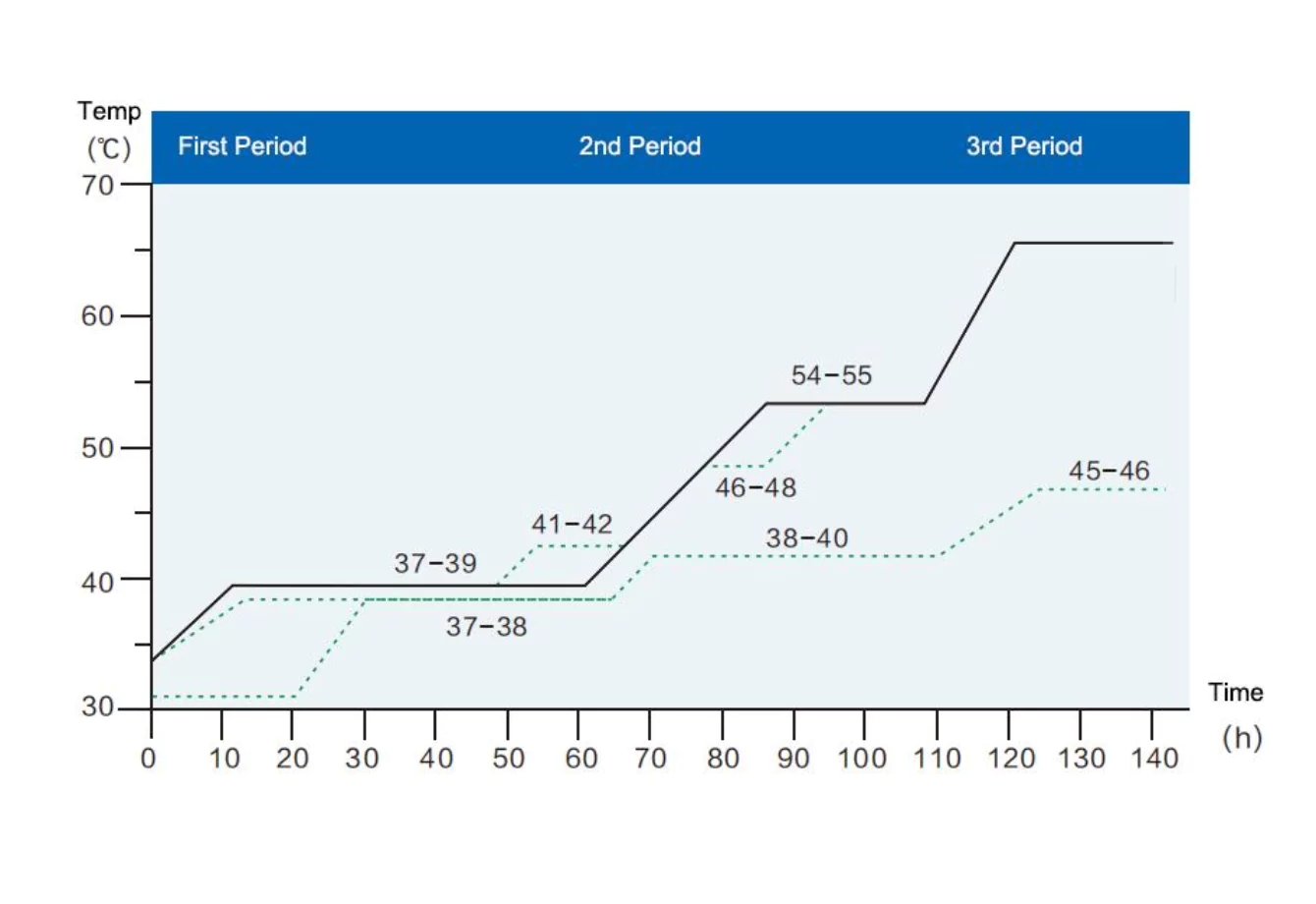

Staged Temperature Control: To dry vegetables quickly and perfectly, we use a staged temperature control method:

- Fast Dehumidification Stage (45-50°C): This stage rapidly removes surface moisture from the vegetables, preventing mold and oxidative browning while preserving their color and shape.

- Stable Drying Stage (50-60°C): We maintain a stable temperature to dry internal moisture, retaining the vegetables’ nutrients, flavor, and texture, ensuring consistent quality.

- Low-Temperature Setting Stage (40-45°C): This helps avoid high temperatures that could damage heat-sensitive compounds (like vitamins, pigments) or lead to an overly hard texture, ensuring stable quality in your dried vegetables.

Automated Control: Our ZN heat pump dehydrator features programmable control. You can set specific heating temperature curves (e.g., initial drying at 50°C, main drying at 60°C, final drying at 45°C). The machine will then automatically adjust temperature and time, so you don’t need constant manual monitoring.

Humidity Management: We keep the relative humidity between 10-15% and include an automatic dehumidification system. Regularly check the exhaust vents to prevent moisture buildup, which can lead to vegetable mold or flavor degradation.

Airflow & Ventilation: Appropriate airflow (0.8-1.5 m/s) speeds up moisture removal. However, too much airflow can cause vegetables to break or dry unevenly. For the initial drying stage, set airflow to 1.2-1.5 m/s, then reduce it to 0.8-1 m/s for the main and final drying stages.

Cooling & Storage: After drying, let the dried vegetables cool naturally to room temperature in a well-ventilated, dry environment. Then, simply seal them in moisture-proof, oxygen-proof sealed bags or containers. Store them in a cool, dark place to prevent moisture reabsorption or nutrient loss.

Vegetable Characteristics: Different vegetables (like leafy greens, root vegetables, fruiting vegetables) vary significantly in moisture content, tissue structure, and heat sensitivity. You’ll need to fine-tune the temperature and time based on the specific variety. For instance, leafy vegetables (e.g., spinach) require lower temperatures (40-50°C) to protect color, while root vegetables (e.g., carrots) can handle slightly higher temperatures (50-60°C) to speed up drying.

If you have specific vegetable types (like leafy greens, root vegetables, or fruiting vegetables) or desired forms (slices, dices, whole) in mind, feel free to contact our experts for a customized heat pump dryer model.

Customizable Control for Optimal Drying

ZN heat pump dehydrators feature built-in control logic with preset heating curves, optimizing drying for various foods. Users can also easily adjust these heating curves to fit specific needs. This ensures your materials are dried to their best condition every time.

Industry-Leading Components for Enduring Quality

All ZN heat pump dehydrators feature key components from industry-leading suppliers. For instance, we use compressors from Copeland and Mitsubishi, and plate heat exchangers from Swep, ensuring both high quality and long service life.

| Model | ZNKBHF-7HCHD/SN3 | ZNKBHF-14HCHD/SN3 | ZNKBHF-14HCHD/SN3-EVI |

| Power Supply | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz |

| Maximum Dehumidification | 20 kg/h | 38 kg/h | 38 kg/h |

| Rated Heating Capacity | 18.5 kW | 37 kW | 37 kW |

| Heat Pump Rated Input Power | 5.95 kW | 11.8 kW | 11.8 kW |

| Heat Pump Rated Input Current | 10.65 A | 21 A | 21 A |

| Electric Heating Power | 9 kW | 18 kW | 18 kW |

| Electric Heating Input Current | 13.7 A | 27 A | 27 A |

| Maximum Outlet Temperature | 75 °C | 75 °C | 75 °C |

| Refrigerant | R134A | R134A | R134A |

| Ambient Temperature | 2~43 °C | 2~43 °C | -7~43 °C |

| Noise Level | 65 dB(A) | 70 dB(A) | 70 dB(A) |

| Safety Protection | High/Low Pressure, Overheat, Overload | High/Low Pressure, Overheat, Overload | High/Low Pressure, Overheat, Overload |

| Operation Control Method | Fully Automatic | Fully Automatic | Fully Automatic |

| Compressor Quantity | 1 | 2 | 2 |

| Compressor Type | Rotary | Rotary | Rotary |

| Indoor Circulation Fan Power | 1.1 kW (1 fan) | 2.2 kW (2 fans) | 2.2 kW (2 fans) |

| Indoor Fan Type | Axial | Axial | Axial |

| Outdoor Fan Power | 0.42 kW (1 fan) | 0.84 kW (2 fans) | 0.84 kW (2 fans) |

| Outdoor Fan Type | Axial | Axial | Axial |

| Dehumidification Fan Power | 0.166 kW (1 fan) | 0.332 kW (2 fans) | 0.332 kW (2 fans) |

| Dehumidification Fan Type | Centrifugal | Centrifugal | Centrifugal |

| Dimensions (W*D*H) | 780*1500*1600 mm | 1530*1500*1625 mm | 1530*1500*1625 mm |