Multifunctional Heat Pump Dehydrator

ZN heat pump dehydrators offer five versatile modes (heating, cooling dehumidifying, automatic constant temperature, automatic drying) for flexible operation.

They feature a quiet DC brushless motor with shock absorption and large blades for better airflow, plus larger evaporators for improved heat exchange and heating efficiency.

- Power: 24 kW, 44 kW, 48 kW

- Voltage: 380V/3Ph/50Hz

- Dehydration Amount: 20 kg/h, 38 kg/h, 50 kg/h (50°C/80%)

- Max Air Outlet Temperature: 60°C (140°F )

Customizable Control for Optimal Drying

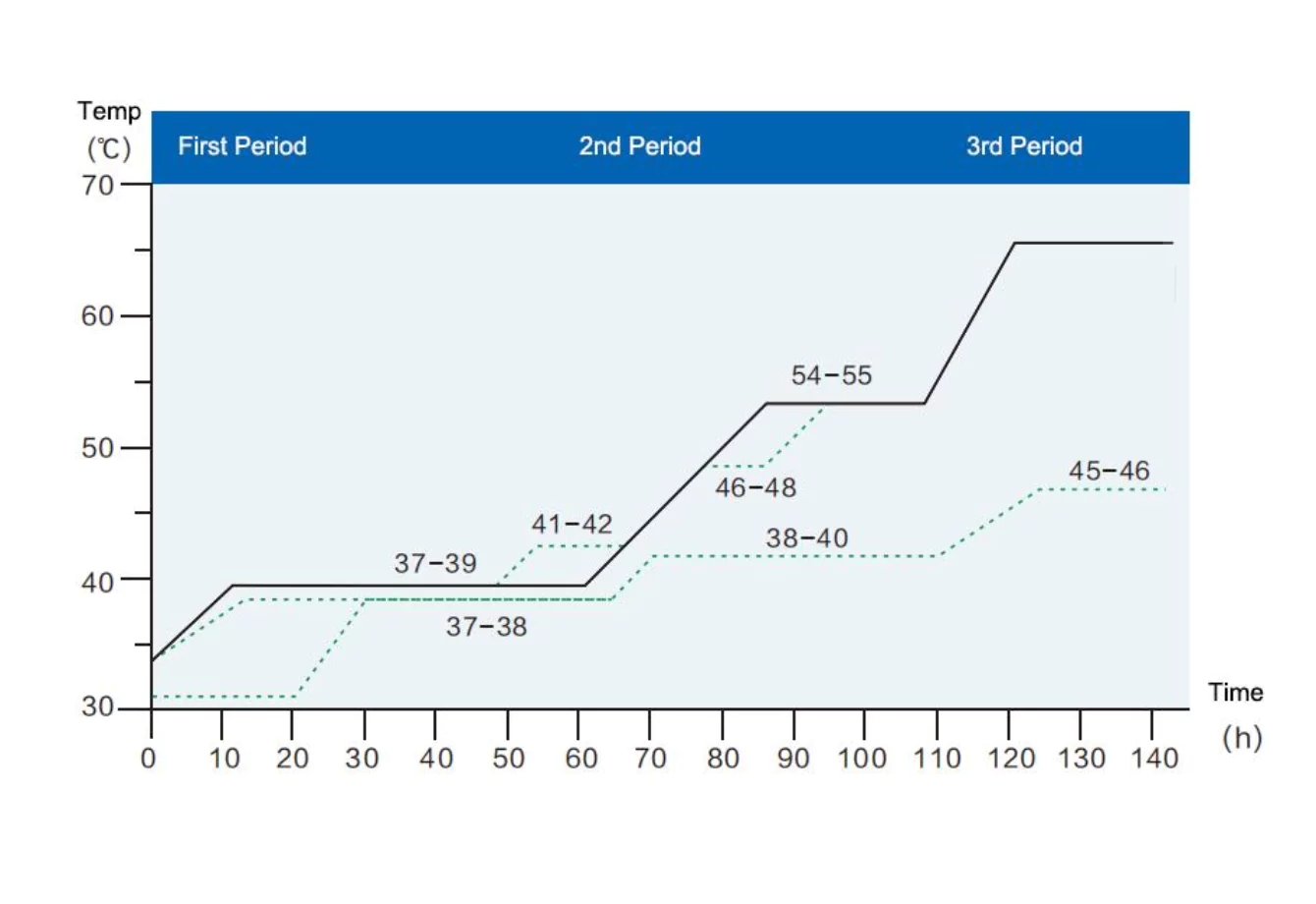

ZN heat pump dehydrators feature built-in control logic with preset heating curves, optimizing drying for various foods. Users can also easily adjust these heating curves to fit specific needs. This ensures your materials are dried to their best condition every time.

Industry-Leading Components for Enduring Quality

All ZN heat pump dehydrators feature key components from industry-leading suppliers. For instance, we use compressors from Copeland and Mitsubishi, and plate heat exchangers from Swep, ensuring both high quality and long service life.

Choose ZN Heat Pump Dehydrators for Diverse Applications

Fish Drying

Meat Curing

Vegetable Dehydration

Nut Drying

Fruit Preservation

Floral Drying

Tobacco and Hops Curing

Industrial Material Drying

| Model | ZNKBHF-7HCHD/SN4-EVI | ZNKBHF-12HCHD/SN4-1 | ZNKBHF-14HCHD/SN4-EVI |

| Power Supply | 380V/3Ph/50Hz | 380V/3Ph/50Hz | 380V/3Ph/50Hz |

| Maximum Dehumidification | 26 kg/h | 40 kg/h | 50 kg/h |

| Rated Heating Capacity | 24 kW | 44 kW | 48 kW |

| Heat Pump Rated Input Power | 7.95 kW | 14.3 kW | 15.8 kW |

| Heat Pump Rated Input Current | 14.2 A | 25.3 A | 28 A |

| Electric Heating Power | 9 kW | 9 kW | 18 kW |

| Electric Heating Input Current | 13.7 A | 13.7 A | 27 A |

| Maximum Outlet Temperature | 60 °C | 60 °C | 60 °C |

| Refrigerant | R417A | R417A | R417A |

| Ambient Temperature | -15~43 °C | -10~43 °C | -15~43 °C |

| Noise Level | 65 dB(A) | 70 dB(A) | 70 dB(A) |

| Safety Protection | High/Low Pressure, Overheat, Overload | High/Low Pressure, Overheat, Overload | High/Low Pressure, Overheat, Overload |

| Operation Control Method | Fully Automatic | Fully Automatic | Fully Automatic |

| Compressor Quantity | 1 | 1 | 2 |

| Compressor Type | Rotary | Rotary | Rotary |

| Indoor Circulation Fan Power | 1.1 kW (1 fan) | 2.2 kW (2 fans) | 2.2 kW (2 fans) |

| Indoor Fan Type | Axial | Axial | Axial |

| Outdoor Fan Power | 0.42 kW (1 fan) | 0.84 kW (2 fans) | 0.84 kW (2 fans) |

| Outdoor Fan Type | Axial | Axial | Axial |

| Dehumidification Fan Power | 0.166 kW (1 fan) | / | 0.332 kW (2 fans) |

| Dehumidification Fan Type | Centrifugal | / | Centrifugal |

| Dimensions (W*D*H) | 780*1500*1600 mm | 1450*1300*1625 mm | 1530*1500*1625 mm |