| Component | Primary Function | Efficiency Impact |

|---|---|---|

| Evaporator Coil | Captures heat from ambient air | High – determines heat extraction |

| Compressor | Pressurizes refrigerant | Critical – drives entire system |

| Condenser | Transfers heat to pool water | High – final heat delivery |

| Expansion Valve | Regulates refrigerant flow | Medium – controls cycle timing |

| Flow Switch | Protects system from dry running | Safety – prevents damage |

| Reversing Valve | Switches heating/cooling modes | Versatility – year-round use |

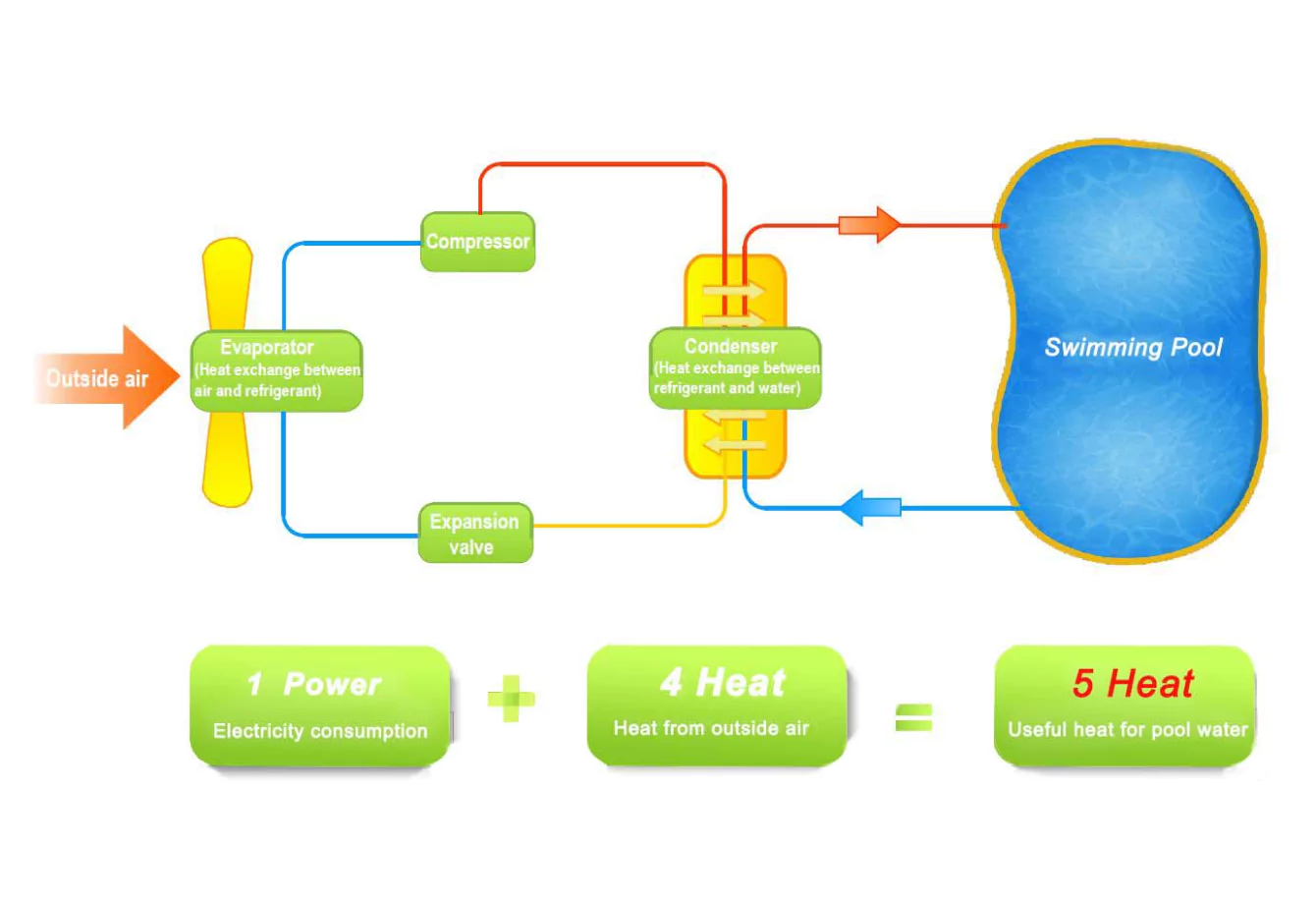

How does a pool heat pump work? In simple terms, pool heat pumps transfer heat from the surrounding air into your pool water using a refrigeration cycle, achieving remarkable efficiency rates of 300-700%. Unlike gas heaters that burn fuel, heat pumps use electricity to move existing heat, making them incredibly cost-effective for pool owners.

This comprehensive guide breaks down every component of pool heat pump systems with detailed diagrams and explanations. Furthermore, we’ll show you exactly how these systems achieve their impressive efficiency ratings and why they’re becoming the preferred choice for modern pool heating.

How Pool Heat Pumps Actually Work (The Simple Explanation)

The 4-Step Heating Process Made Simple

Understanding how pool heat pumps work becomes easy when you break it down into four simple steps. First, the evaporator coil captures heat from the ambient air, even when outdoor temperatures are as low as 40°F. Next, the compressor pressurizes the refrigerant, dramatically increasing its temperature. Then, the heated refrigerant flows through the condenser, where it transfers its heat to the pool water. Finally, the expansion valve reduces the refrigerant pressure, completing the cycle and preparing for the next round of heat extraction.

This process repeats continuously while your heat pump operates, gradually raising your pool water temperature. Moreover, the system automatically adjusts its operation based on your desired temperature setting, ensuring consistent comfort without wasting energy.

“The beauty of heat pump technology lies in its ability to multiply energy. For every unit of electricity consumed, a quality heat pump delivers 3 to 7 units of heat energy to your pool. It’s like getting a 300-700% return on your energy investment.” – Dr. Michael Stevens, HVAC Systems Engineer

Why Heat Pumps Achieve 300-700% Efficiency

The secret behind pool heat pump efficiency lies in the fact that they don’t create heat – they simply move it from one place to another. This fundamental difference from gas heaters explains why heat pumps can achieve Coefficient of Performance (COP) ratings between 3.0 and 7.0, meaning they produce 3 to 7 times more heat energy than the electrical energy they consume.

Additionally, the refrigeration cycle amplifies the available heat through compression and expansion. When the compressor pressurizes the refrigerant, it concentrates the heat energy, making it hot enough to warm your pool water effectively. This process works efficiently even when outdoor air temperatures seem too cool for heating.

Essential Components and What They Do

Evaporator Coil: The Heat Collector

The evaporator coil serves as your heat pump’s primary heat collection system, designed to extract thermal energy from ambient air even in surprisingly cool conditions. This component consists of copper or aluminum tubing arranged in a fin-and-tube configuration that maximizes surface area for heat transfer. Furthermore, the coil design allows refrigerant to absorb heat efficiently while maintaining proper flow rates throughout the system.

Modern evaporator coils can extract usable heat from air temperatures as low as 40°F, though efficiency decreases as temperatures drop. The coil’s performance directly impacts your heat pump’s overall efficiency, making proper maintenance crucial for optimal operation. Additionally, the evaporator coil works in conjunction with a variable-speed fan that draws air across the coil surface, ensuring consistent heat extraction.

Regular cleaning of the evaporator coil prevents dust and debris buildup that can reduce heat transfer efficiency. Moreover, proper airflow around the coil is essential – obstructions like leaves, grass, or nearby structures can significantly impact performance and increase operating costs.

Compressor: The Power Booster

The compressor functions as the powerhouse of your pool heat pump system, responsible for pressurizing refrigerant and driving the entire heating process. This component uses electrical energy to compress the refrigerant gas, dramatically increasing both its pressure and temperature. Consequently, the compressed refrigerant becomes hot enough to transfer its heat effectively to your pool water.

Modern pool heat pumps typically use scroll or rotary compressors, which offer superior efficiency and reliability compared to older reciprocating designs. These compressors operate more quietly and provide better temperature control, making them ideal for residential pool applications. Additionally, variable-speed compressors can adjust their output based on heating demands, further improving efficiency and reducing operating costs.

“The compressor is like the engine of your car – it’s the most critical component that determines performance and longevity. Investing in a heat pump with a quality compressor and proper warranty coverage pays dividends over the system’s 15-20 year lifespan.” – Jennifer Walsh, Pool Equipment Specialist

Condenser/Heat Exchanger: Where the Magic Happens

The condenser or heat exchanger represents the final stage where thermal energy transfers from the refrigerant to your pool water. This component typically consists of titanium or cupro-nickel tubing designed to withstand chlorinated pool water while maximizing heat transfer efficiency. Furthermore, the condenser’s design ensures optimal flow rates for both refrigerant and pool water, maintaining consistent heating performance.

Pool water circulates through the condenser while hot refrigerant flows around the water tubes, creating an efficient heat exchange process. As the refrigerant releases its heat, it condenses back into a liquid state, completing the thermal transfer cycle. Additionally, modern condensers include features like turbulators or enhanced surface designs that improve heat transfer rates.

The condenser’s performance directly affects your heat pump’s heating capacity and efficiency. Regular inspection for corrosion, scaling, or debris ensures optimal heat transfer and prevents costly repairs. Moreover, proper water chemistry helps maintain condenser integrity and extends system lifespan significantly.

| Component | Expected Lifespan | Replacement Cost | Maintenance Frequency |

|---|---|---|---|

| Evaporator Coil | 12-15 years | $400-$800 | Monthly cleaning |

| Compressor | 15-20 years | $1,200-$2,000 | Annual inspection |

| Condenser | 10-15 years | $600-$1,200 | Bi-annual inspection |

| Expansion Valve | 10-12 years | $150-$300 | Annual calibration |

Expansion Valve and Flow Controls

The expansion valve serves as a critical control component that regulates refrigerant flow and pressure throughout your heat pump system. This precision device reduces the high-pressure liquid refrigerant from the condenser to a low-pressure mixture, preparing it to absorb heat in the evaporator coil. Furthermore, the expansion valve’s proper operation ensures optimal system efficiency and prevents damage from improper refrigerant flow rates.

Modern heat pumps use thermostatic expansion valves (TXV) or electronic expansion valves (EXV) that automatically adjust based on system conditions. These advanced valves provide precise control over refrigerant flow, maintaining optimal superheat levels and ensuring consistent heating performance. Additionally, proper expansion valve operation prevents liquid refrigerant from reaching the compressor, which could cause severe damage.

Flow switches represent another crucial control component that protects your heat pump from operating without adequate water flow. These safety devices monitor pool water circulation and automatically shut down the heat pump if flow drops below safe levels. Moreover, flow switches prevent overheating and extend system lifespan by ensuring proper heat dissipation during operation.

Pool Heat Pump Plumbing and Water Flow

Step-by-Step Water Circulation Process

Understanding pool heat pump plumbing begins with following the complete water circulation path from your pool through the heating system and back. Initially, your pool pump draws water from the skimmer and main drain, creating the circulation flow that powers the entire system. This water then travels through the pump’s impeller, which pressurizes it for efficient flow through the filtration and heating equipment.

After leaving the pool pump, water flows through your filtration system to remove debris and contaminants before entering the heat pump. This sequence is crucial because clean water prevents damage to the heat pump’s internal components and maintains optimal heat transfer efficiency. Subsequently, the filtered water enters the heat pump’s condenser, where it absorbs heat from the refrigerant system.

Finally, the heated water returns to your pool through the return jets, completing the circulation cycle. The entire process typically moves your pool’s water volume through the heating system multiple times per day, gradually raising the overall temperature to your desired level. Moreover, proper water flow rates ensure efficient heat transfer and prevent hot spots or uneven heating throughout your pool.

Bypass Valve Setup and Why You Need It

A properly configured bypass valve system provides essential flexibility and protection for your pool heat pump installation. These valves, typically 3-way Jandy or similar designs, allow you to control water flow through or around your heat pump as needed. Furthermore, bypass valves enable maintenance activities without shutting down your entire pool circulation system, maintaining water quality during service periods.

The bypass configuration includes an inlet valve that controls flow into the heat pump and an outlet valve that manages flow back to the pool. Additionally, a bypass line connects these valves, allowing water to flow directly from the filtration system back to the pool when the heat pump is offline. This setup proves invaluable during maintenance, repairs, or when heating isn’t needed.

Proper bypass valve operation also protects your heat pump from excessive flow rates that could damage internal components. By adjusting the valves, you can optimize flow rates for maximum heating efficiency while ensuring adequate circulation for your pool’s filtration needs. Moreover, bypass valves allow you to isolate the heat pump for winter storage in colder climates.

Proper Placement After Filtration System

Heat pump placement in your pool’s plumbing system follows a critical sequence that ensures optimal performance and longevity. The heat pump should always be installed after your filtration equipment, including the pool pump, filter, and any additional water treatment devices. This arrangement ensures that clean, filtered water enters the heat pump, preventing debris from damaging sensitive internal components.

Installing the heat pump before filtration equipment exposes it to dirt, leaves, and other contaminants that can clog the condenser tubes and reduce heat transfer efficiency. Additionally, debris can cause premature wear on the heat pump’s internal components, leading to costly repairs and reduced system lifespan. Therefore, the proper sequence is: pool pump → filter → heat pump → return to pool.

“I’ve seen too many heat pump failures caused by improper plumbing placement. Installing the heat pump after filtration isn’t just a recommendation – it’s essential for warranty coverage and long-term reliability. Clean water is happy water for heat pumps.” – Tom Rodriguez, Pool Service Professional

Common Plumbing Mistakes to Avoid

Several pool heat pump installation mistakes can significantly impact system performance and longevity. One of the most common errors is insufficient pipe sizing, which restricts water flow and reduces heating efficiency. Heat pumps require adequate flow rates for optimal heat transfer, typically 30-50 gallons per minute depending on the unit size.

Another frequent mistake involves improper valve placement or orientation, which can create air pockets or flow restrictions. Additionally, failing to install a flow switch or installing it incorrectly can leave your heat pump vulnerable to damage from low-flow conditions. The flow switch should be installed in the return line after the heat pump to ensure accurate flow detection.

Inadequate support for plumbing connections can lead to stress on the heat pump’s fittings, potentially causing leaks or damage over time. Furthermore, using incompatible materials or fittings can result in corrosion, leaks, or chemical reactions that compromise system integrity. Always use materials rated for pool applications and follow manufacturer specifications for all connections.

Conclusion: Mastering Your Pool Heat Pump System

Understanding how pool heat pumps work empowers you to make informed decisions about installation, maintenance, and operation of your heating system. The sophisticated refrigeration cycle that achieves 300-700% efficiency represents a remarkable advancement in pool heating technology, offering both environmental benefits and substantial cost savings over traditional gas heaters.

From the evaporator coil that captures ambient heat to the condenser that transfers it to your pool water, each component plays a crucial role in delivering reliable, efficient heating. Moreover, proper plumbing design and installation ensure optimal performance while protecting your investment for the system’s 15-20 year lifespan.

Take Action for Optimal Pool Heating

Ready to maximize your pool heat pump’s performance? Start implementing these insights today:

- Schedule Professional Inspection: Have a qualified technician evaluate your current system’s components and plumbing configuration

- Implement Regular Maintenance: Clean evaporator coils monthly and check all components according to the maintenance schedule provided

- Optimize Your Plumbing: Ensure proper bypass valve setup and verify correct installation sequence for maximum efficiency

- Monitor Performance: Track your system’s COP and energy consumption to identify potential issues early

- Plan for Upgrades: Consider component replacement schedules and take advantage of available efficiency incentives

Don’t let inefficient heating drain your wallet. Contact certified pool professionals in your area to assess your system and implement the improvements discussed in this guide. Your pool – and your energy bills – will thank you for the investment in proper heat pump operation.